Asphalt Recyclers

Hot asphalt mix right at the building site, at low cost

Fast and resource-conserving production of up to 10 tonnes of asphalt mix every hour. The recycler uses waste asphalt or milled material to make new base layers. Bagela is the patent-holding world market leader in this "green" niche market.

Benefits:

- Hot asphalt mix available in just 10 minutes – at any time and any place

- Elimination of material, transport and disposal costs

- Avoidance of hazardous waste thanks to 100% recycling

- The recycling of 1 tonne of asphalt requires just 6 litres of fuel

The Bagela asphalt recycler proves its worth wherever asphalt needs to be applied manually.

Asphalt Recycler BA 7000F and BA 10000F

- environmentally friendly

- independent

- cost-saving

Don’t complain about high prices of mineral oil and bitumen, if you are carrying the broken asphalt or the milling material to the dumping ground over and over again!

- independent – Hot material everywhere and at every time!

- environmentally friendly – No transport charges, no waste of resources, no dumping of asphalt!

- cost saving – 6 Litre fuel oil = 1 to asphalt base layer.

National and international comparison analysis supply evidences for: High quality base layer can be developed from broken asphalt (base and top layer) only by competent handling of the Bagela asphaltrecycler.

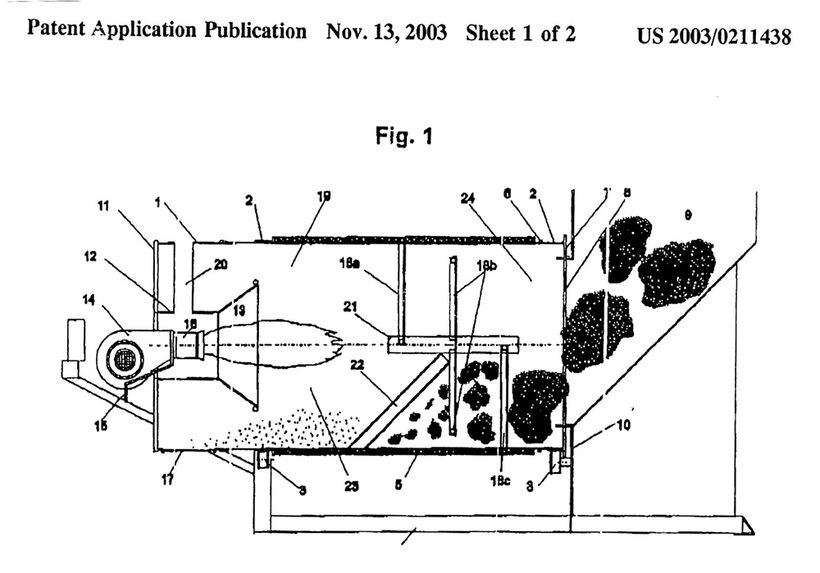

A new mixing drum system has been designed for processing asphalt fines or for drying soil. The drum is provided with high axial webs, which, in combination with a higher mixing speed, ensure increased heat absorption by the processed material.

For discharging the heated asphalt direct at the place of application (pipe or cable trench), the Recycler BA 7000 F may optionally be equipped with a traction drive.

Painting: traffic red RAL 3020

These high axial segments fixed inside of the mixing drum prevent the premature escape of heat and ensure the absorption. The broken asphalt lumps warm up while passing the segments and reach the heating section as small fines. In the heating section the material is heated up by radiant heat, but mainly by the hot wall of the mixing drum.

After 10 minutes of heating the discharging gate has to be opened. Depending on the material and with continuous loading the output of the Asphalt Recycler BA 7000 is up to 7 tonne/h and the BA 10000 up to 10 tonne/h.

Specifications are subjects to change without notice, output details are depending on use conditions